-

Gildale Farms 2913B Rd 122, R.R.#7

St. Mary's, ON, Canada

N4X 1C9 -

Call Us +1(519) 267-5079 WhatsApp: +1 (703) 646-6735

-

Mail Us gildalefarms.ca@gmail.com

Gildale Farms

2913B Rd 122, R.R.#7

St. Mary's, ON, Canada

N4X 1C9

Call Us +1(519) 267-5079 WhatsApp: +1 (703) 646-6735

Mail Us gildalefarms.ca@gmail.com

To create a great wood pellet product, we source high quality biomass from diverted wood streams and input the material through an intensive manufacturing process. Our facility produces approximately 5000 tons of wood pellets every year.

Click on the video below to see how we make the pellets!

Wood Biomass

Animal Bedding Biomass

Premium Biomass

Unloading Source Material

Wood biomass is sourced as a byproduct of timber production, and furniture manufacturing. The material is stored at our manufacturing facility and separated into each grade of wood. A loader is used to move the wood biomass into the manufacturing process.

Wood biomass is loaded into a bin to be fed into a grinder. A magnet pulls out any metal in low grade wood. The biomass then enters the grinder which reduces the wood into small fibres. The wood fibre is transported from the grinder to the pelleting process using a pneumatic takeaway system.

Loading The Biomass

Magnet

Grinder

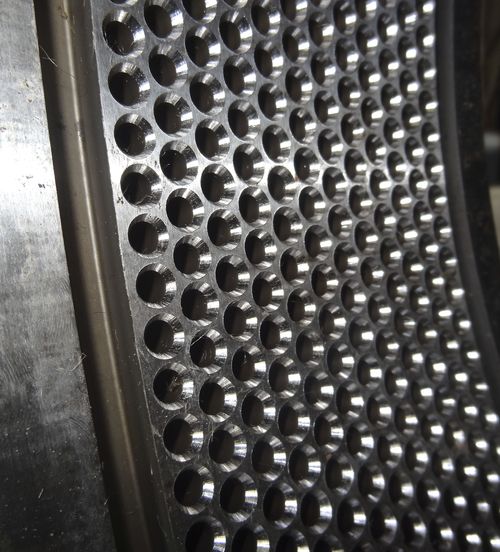

Metal Die

Pellet Mill

The wood fibre enters the pellet mill where it is extruded at high pressure through narrow holes in a thick metal die.

Pellets travel to a cooling tank where a fan pulls air through the pellets to remove heat generated by the extruding process. Dust is also removed in this stage using a large fan and recycled back into the manufacturing process to be made into pellets.

Cooling Tank

Large Fan

Storage Bins

Pellets are packaged in 40 lb bags or tote bags to be delivered on 1 ton skids.